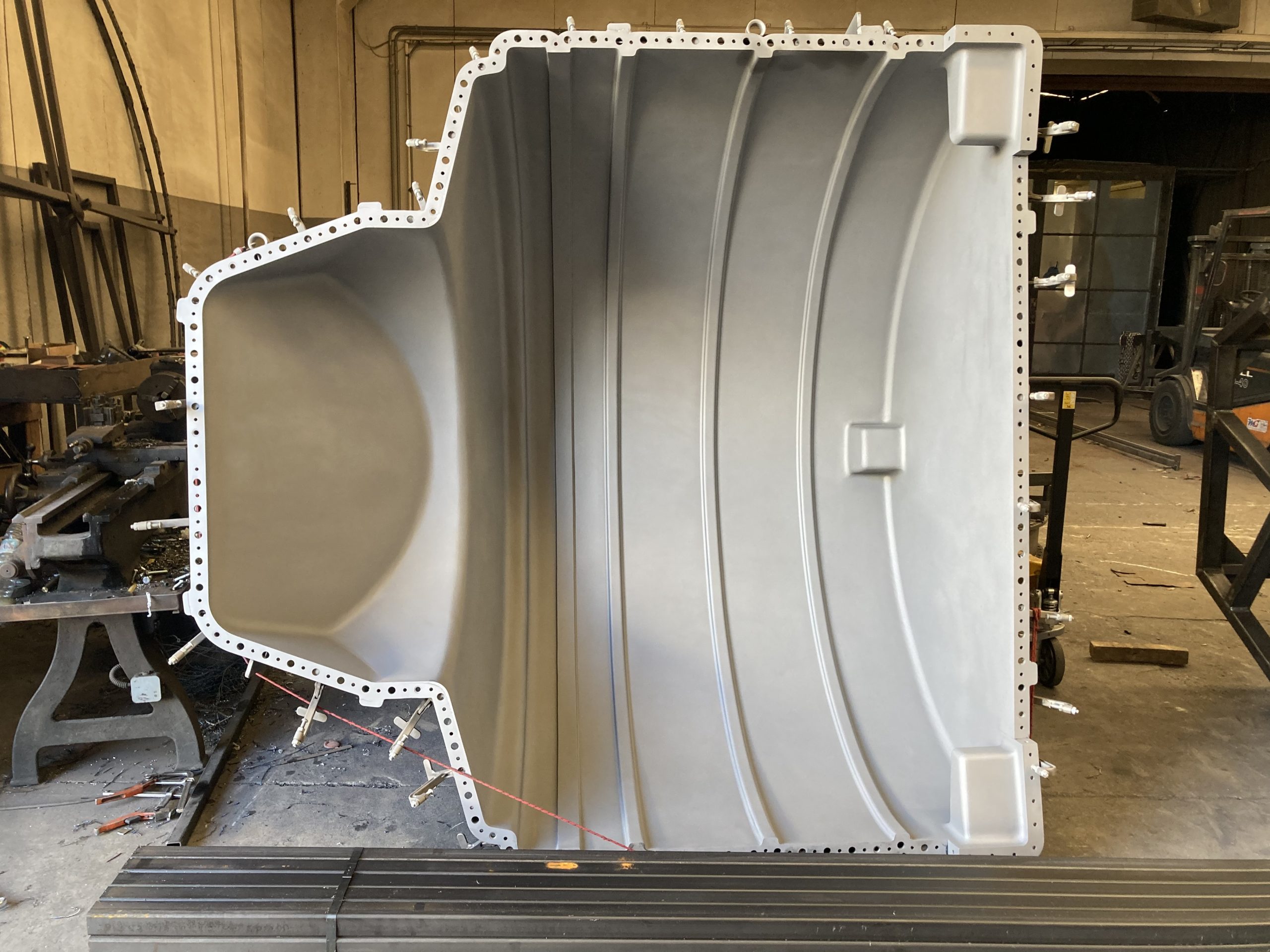

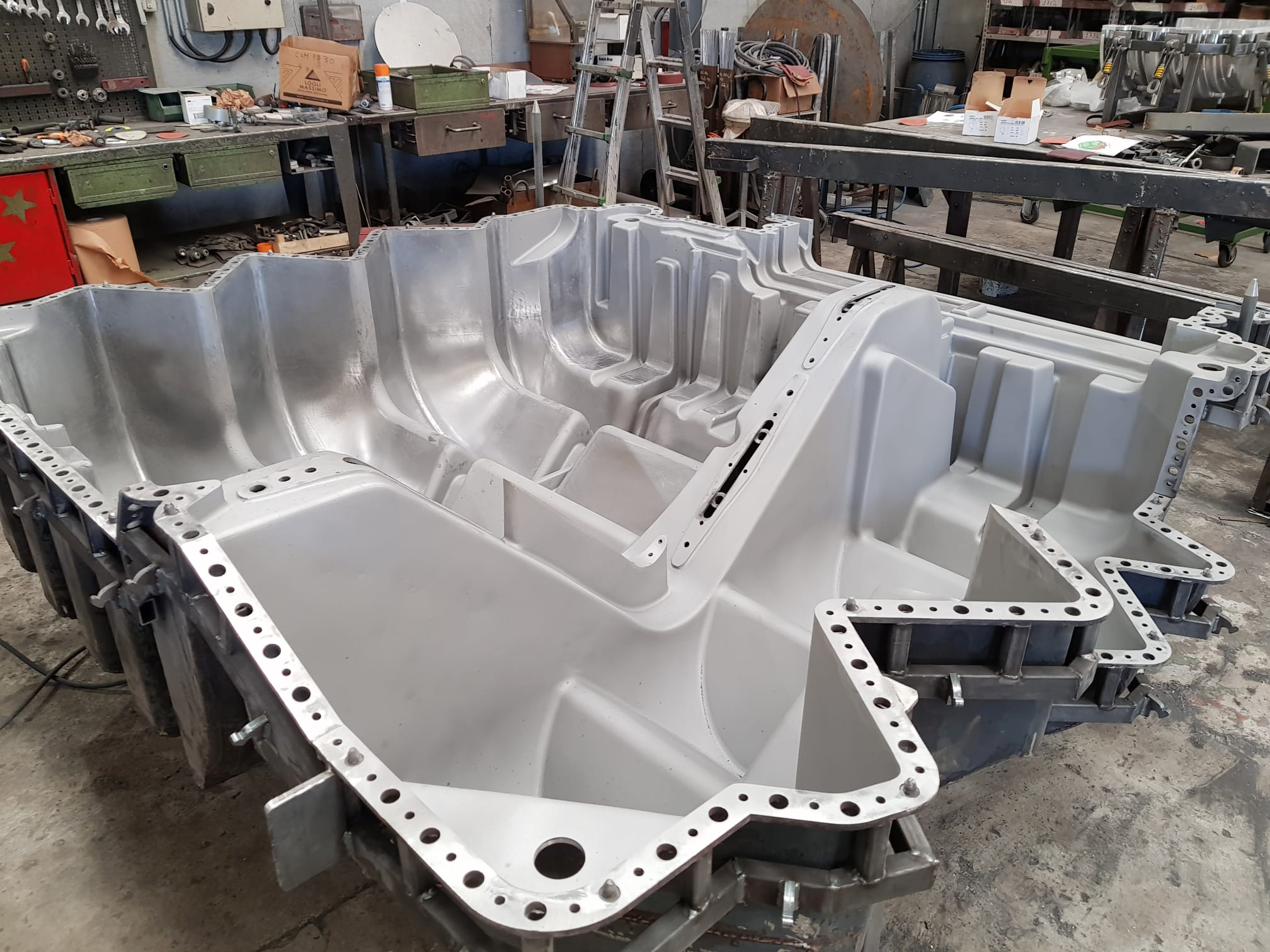

Steel sheet moulds for Rotational Moulding

Sheet steel moulds

Steel sheet rotational moulds are essential for the production of large plastic products, such as outdoor tanks, underground pits for rainwater recovery or wastewater treatment. Due to the durability of steel, these moulds are able to withstand the thermal and mechanical stresses of the rotational moulding process, offering reliable and consistent performance.

Stainless steel sheet moulds

Stainless steel sheet rotational moulds are a high-quality solution for the production of plastic products. Stainless steel offers resistance to corrosion and high temperatures, making the moulds ideal for applications requiring high performance and longevity. They also provide a shinier surface finish where required.

The sheet metal mol ds for rotational moulding produced by RotoMoulds are the result of careful design and attention to detail. Using advanced CAD software and the experience of their experts, RotoMoulds is able to create moulds that meet high standards of precision and quality.

During the design process, several critical factors are considered. The geometry of the final product, the frame structure, and any and all heating problems. In addition, RotoMoulds goes to great lengths to understand the specific cooling needs of the equipment to ensure efficient production and optimized cycle times.

Sheet metal mould making requires specialized skills and state-of-the-art technology. RotoMoulds uses techniques such as laser cutting to achieve high precision and perfect alignment. External and internal welds, which are then finished by grinding, ensure a strong and solid structure, while high-temperature heat treatments give the cheesecloth greater stability and durability.

In addition to this, RotoMoulds also offers customizations to meet customers’ specific needs. Customer logos, recycling indications and date stamps can be included directly on the moulds, ensuring a unique and customized product.

RotoMoulds’ sheet metal moulds are critical to the manufacturing process of plastic products. Their quality and functionality enable the production of large objects and complex shapes, such as tanks, containers and components for the automotive industry.

Contact us